Let’s Talk Nitrogen and Purity Vs. Cleanliness

What does the “purity” specification mean? Ultimately, it doesn’t mean purity in the traditional sense of the word. According to dictionary.com, the definition of purity is the condition or quality of being pure; freedom from anything that debases, contaminates, pollutes, etc. When speaking about nitrogen though, the term purity only covers one single “contaminant”, which really isn’t a contaminant at all…It’s oxygen. Purity, in our world, refers to the allowable oxygen left in the nitrogen that is produced. Different industries and applications have different purity requirements and all are dictated by how much oxygen their process can handle before adversely affecting the product. Since it is oxygen that is what can cause issues (i.e. oxidation in laser cutting, food spoiling in food and beverage packaging, or corrosion in a boiler during layup), it is the strategic elimination of the oxygen that is critical.

Why Understanding Purity Levels Is Crucial for Your Application

If the nitrogen purity is too high, the process will gain no additional benefit but will be more expensive to purchase. The system will be more cost-intensive to operate resulting in a higher than necessary price for the nitrogen produced. If the nitrogen purity is too low then the product or process will suffer. The purpose of this article is not to highlight what purity levels different applications require or to tell you about how and why you should be selective in specifying purity (i.e. Nitrogen Purity: What Do I Need to Know and Why Is It Important?). The purpose is to highlight that the term “purity” might not mean what you think it does…

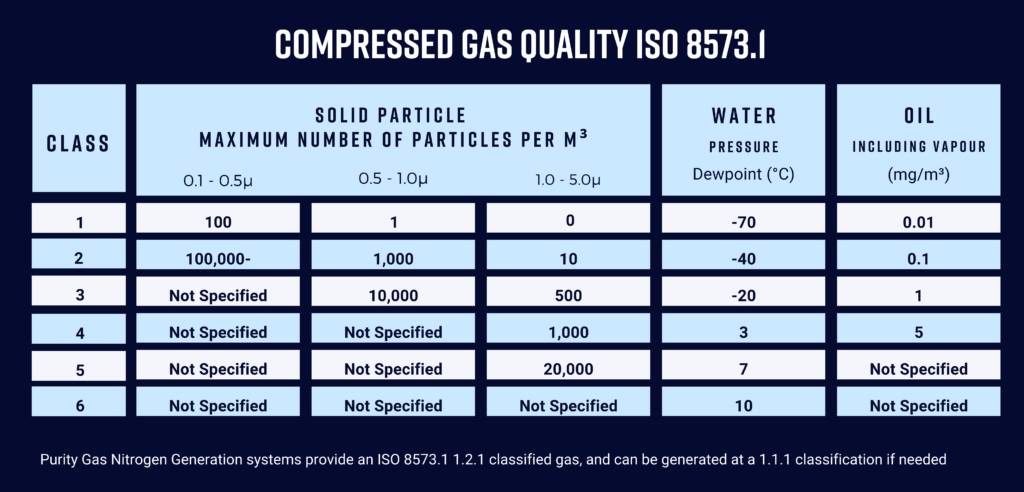

When describing and classifying the other contaminants (solid particulate, water, and oil) the term “quality” is used. The ISO classification 8573.1 specifies the quality of compressed air with respect to particles, water, and oil. The ISO uses the term purity (correctly) to determine these classifications. The trouble is relative to nitrogen, this industry has used the term purity and has overridden its actual definition, redefining it to mean the amount of allowable oxygen.

So What Does This Matter or Mean?

Ultimately, when you are speaking about nitrogen, you can have high quality with low purity and be perfectly suited for the application. For example, a purity level of 99.5% is the standard in the food and beverage space and is relatively low purity. However, it is critical that the nitrogen is of the highest quality (minimal solid particulate, water, or oil present).

There are few, if any processes that would need high purity levels, but accept low-quality nitrogen. In the case of Purity Gas Nitrocenter generation systems, all nitrogen generated is classified as ISO 8573.2:2010 1.2.1.

This means there is:

So whether it is a high or low purity application, you will always have the highest quality. The classifications are spelled out below:

Knowing the difference, and understanding that your nitrogen purity level is application-specific and relative to oxygen content, and the quality level is truly the level of cleanliness will be critical in helping you to determine the actual required purity for your application.

To Sum It All up

When discussing nitrogen gas:

Purity is the amount of remaining oxygen.

Quality is how clean (or “pure” as defined by dictionary.com) the nitrogen is.

Contact us to learn more about how nitrogen gas generation can contribute to your financial, operational and sustainability initiatives.

by Brett Rogers

by Brett Rogers