What Makes Nitrogen Generation a Sustainable Solution?

There may be misconceptions and perceived downfalls of nitrogen generation but truthfully, nitrogen generation is a sustainable solution to the realities we face in the world today. The overall process is very simple and is therefore very reliable; and there are no harmful byproducts.

There are two types of nitrogen generators (membrane and PSA) and both types operate in a similar fashion. The two requirements are compressed air and 120 VAC power…That’s it! The entire nitrogen generation system can be seen as an addition to the compressed air system that most facilities already have. The amount of air that the nitrogen generation system requires is very dependent on the purity, pressure and flow rates determined by the industry requirements. More often than not, additional compressed air is necessary to feed the nitrogen generators but it shouldn’t be seen as adding any complexity. We can simply use excess capacity or incorporate additional compressed air equipment to the centralized system, or supply a stand alone compressor dedicated to the nitrogen gas generation system.

Purity Gas nitrogen generators are all modular, contributing to system efficiency, have hassle-free maintenance due to redundancy and allow future expandability without having to replace the existing system.

So, You Ask… What Can Go Wrong?

The reality is, misfortunes can arise – leading us to the ultimate question: what happens in the event of a power failure? The systems require 120V at less than 2A to operate but the bigger issue is that there will be no incoming compressed air because the air compressor will be down….In the event of a power failure, here’s what we would suggest to keep the system running:

The Key to Achieving a Sustainable System Is System Design

We cannot predict when the next storm will hit or if a vehicle is going to hit a utility pole but we do have contingency plans to keep vital systems and processes online.The compressed air system is comprised of many mechanical components which are all subject to wear and will experience the occasional breakdown. As previously mentioned, the nitrogen generation system can be decoupled from the compressed air system and can be fed by portable compressors. Alternatively, if the nitrogen generation system has a dedicated air compressor and if the plant air compressor has a mechanical or electrical failure, the dedicated air compressor can be valved so that it can support the plant as well (it can act as a form of redundancy).The key to achieving a sustainable system is good system design, actively monitoring the system and performing routine preventative maintenance. The design of the nitrogen generator is simple and resilient; there are a few solenoid valves which control the flow of air through a media that separates the nitrogen from the air, there are no other moving parts. The generators require very little maintenance, which can be done by in-house mechanics/millwrights or any of our qualified service providers. The nitrogen generators have been built with quality materials and have a service life of over 10+ years before any media requires replenishment.

The Importance of a Nitrogen Demand Analysis

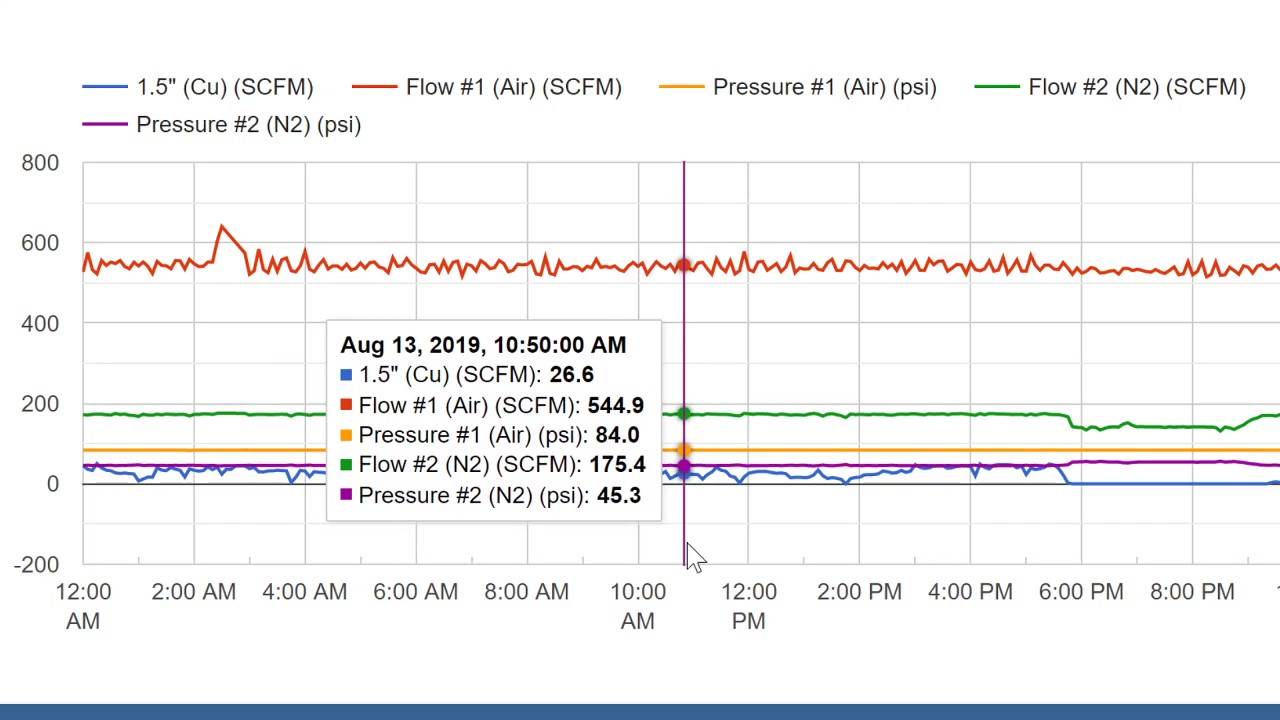

The system should also be designed to meet the peak demands of a plant or process while being able to run efficiently when supplying the average demands. In order to do this, we perform A Nitrogen Demand Analysis and then design the system with the appropriate air quality. The design will affect the nitrogen purity, system pressure and output flow rates.When designing a system, we look at how much nitrogen gas is required (flow rate), what purity is required (the minimum allowable oxygen content) and working pressure (process or equipment downstream). The nitrogen generators (PSA or Membrane) have to be appropriately sized and require a steady input of air.

Nitrogen Demand Analysis

Flow and Air Quality Supports Performance Reliability

The flow and quality of the input air will greatly affect the system performance and therefore it’s reliability. The system performs best when it is coupled to a compressed air supply with a stable pressure profile. When designing a system, we also consider the amount of air and nitrogen gas which needs to be stored in order to meet the flow profile of a process without overloading a system.

We have designed many systems for use in various industries so we can confidently say that each application is different and requires a unique solution. We also offer preventative maintenance services across North America. Please see our case studies and contact us for more information.

by Dalvir Jandu, P.Eng.

by Dalvir Jandu, P.Eng.