The Challenge

Production floor space is highly coveted in most manufacturing and processing facilities. Occupying valuable indoor real estate with utility based equipment can present a challenge to a growing business attempting to maximize its production area. Although on-site nitrogen gas generation will provide the lowest price for nitrogen, not all facilities have the available indoor floor space to accommodate the gas production equipment.

Traditionally, bulk liquid nitrogen had an advantage in where it is stored. High volume nitrogen users will erect a bulk storage tank outside of their building, which is filled with liquid nitrogen. Although convenient in its location, this approach comes at a financial and operational cost to the end user. Unfortunately, this is the perceived trade off to preserving the finite, indoor production space.

Complications with Bulk Liquid Nitrogen

Our Approach

The Purity Gas engineering team saw an opportunity to help nitrogen users capitalize on the benefits of on-site gas generation, without having to surrender any indoor real estate.

A Canadian based business in the metal fabrication industry was motivated to reduce their nitrogen expense. While exploring options, they discovered that nitrogen gas generation could provide a solution to the financial, operational and safety concerns associated with traditional bulk liquid supply. Although motivated to convert to nitrogen gas generation, indoor floor space was not available to accommodate the equipment.

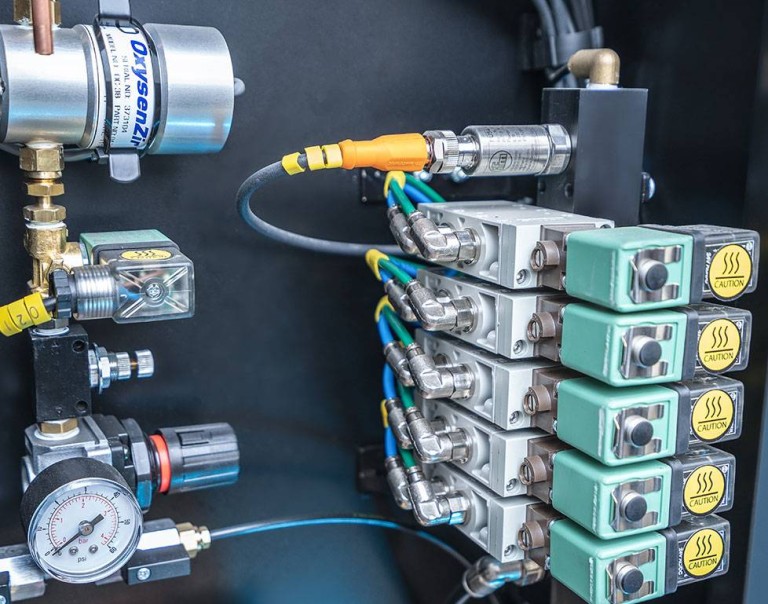

Understanding the client’s motivations and challenges, Purity Gas engineered a fully integrated and weatherproof solution which could be installed in the same outdoor location as the existing bulk liquid storage tank. This solution offered the financial and operational gains that the client was seeking, without sacrificing any usable production floor space. All of the manufacturing, fabrication and assembly was completed offsite, eliminating any business interruption. In under five hours, the bulk liquid nitrogen tank was removed and the nitrogen gas generation system was installed in its place. Production was supplemented with bulk pack nitrogen cylinders while the changeover occurred.

%

Cost Reduction

years

Payback Period

tC02e

Eliminated Annually

Case Summary

Containerized nitrogen gas generation systems can be an ideal solution for nitrogen users who are seeking cost reduction opportunities associated with their nitrogen supply, but unwilling to forfeit valuable floor space. Each containerized system is custom built for the user and engineered to satisfy the flow, purity and pressure requirements of the facility.

System Details

Contact us for a free assessment and to learn more about how nitrogen gas generation can contribute to your financial, operational and sustainability initiatives.

by Purity Gas Inc.

by Purity Gas Inc.