The Challenge

Purchasing Nitrogen Can Be Expensive

Now more than ever, high volume nitrogen users are seeking cost reduction opportunities without operational compromise. On-site nitrogen generation for laser cutting applications are being adopted at a rapid rate for their low operating costs, flexible purity range and ability to produce an endless supply of nitrogen gas, on-demand.

A progressive, high volume laser cutting facility in Canada was searching for ways to become self-sufficient and reduce their ever-increasing nitrogen expenses. They discovered that replacing the bulk liquid nitrogen tank with on-site nitrogen gas generation technology would substantially reduce costs and provide layers of redundancy which did not exist with bulk liquid supply. The client required a solution which would be optimized for today, but also allow for future plant expansion.

Nitrogen for Laser Cutting

In laser cutting applications, nitrogen gas is predominantly used to displace oxygen around the cutting area while the laser beam is in contact with the material being processed. Purging the beam path with high purity nitrogen gas will produce an oxidation free finish, ensuring optimum surface appearance and material integrity. Properly configuring the purity, pressure and volume of the nitrogen assist gas is critical to achieving an optimum result at the lowest possible cost per cut. The material type, material thickness and desired finish will dictate how the assist gas is configured. A reliable and inexpensive supply of nitrogen gas is imperative for facilities processing stainless steel, carbon steel and aluminum.

Our Approach

Thoroughly Assess and Present the Facts

Working closely with the facility engineering team, we developed a solution which would support the plant in the present and future, without compromising the system efficiency. Over-sizing a single nitrogen gas generator can be an expensive journey while the plant is trying to grow into it, while sizing the equipment for today and undertaking a large retrofit project in the near future can also be costly. The client required an efficient solution for today and tomorrow.

Purity Gas completed a comprehensive nitrogen usage assessment of the plant and its processing equipment to determine the following:

Nitrogen Purity

We analyzed the materials and processing equipment to create a tailored purity solution that would provide the client with the lowest cost per cut. Each material being processed will have a maximum allowable tolerance for oxygen. Allowing too much oxygen into the process will compromise the quality of the finished product. Inversely, engineering the system to remove too much oxygen may not provide any additional benefit, but will cost much more to generate. It is critical to provide a nitrogen purity level that will satisfy the optimum needs of the process, without over purifying the nitrogen to the point of diminishing return.

Modular N2 Generation Vs. Bulk Liquid

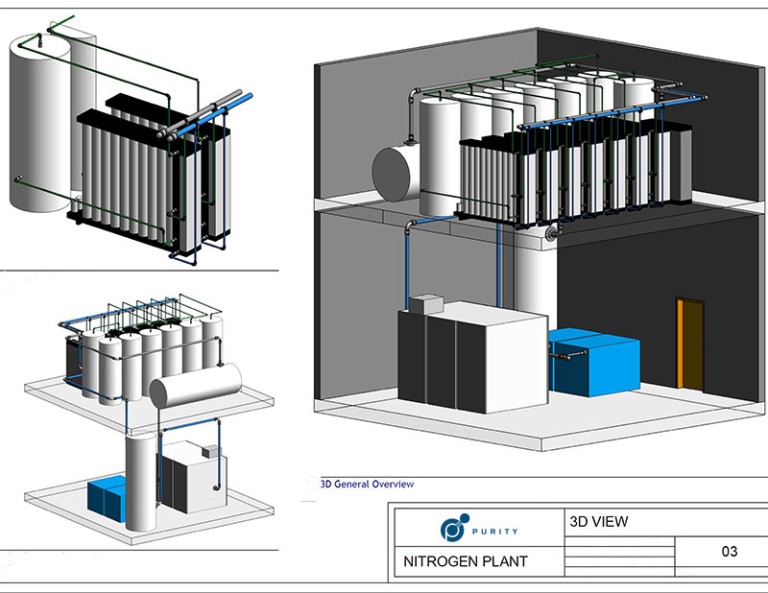

During reduced production periods, the full capacity of the system may not be required. Our modular approach will allow the system to scale down its gas production duties and isolate the unneeded modules during low demand periods. As production increases, the system will scale up by awakening modules from eco-mode, ensuring that peak demand is satisfied. Simply put, this control strategy creates an environment where modules will operate, only when they are required. This efficient process avoids unnecessary wear and tear and the loss valuable compressed air.

The Business Case

The business case and executive summary were presented clearly and with objective transparency; we let the numbers talk. Our comprehensive and detailed assessment eliminated all guess work and enabled the client to make a well-informed decision for their company, with confidence.

%

Cost Reduction

years

Payback Period

tC02e

Eliminated Annually

Case Summary

Reduced Costs & Increased Dependability

Since commissioning the system in early 2019, the client has cancelled their bulk liquid supply contract and is enjoying the cost reduction, environmental and operational benefits of on-site nitrogen generation.The client has reduced their overall nitrogen expenses by 69% and will eliminate over 18 tonnes of carbon dioxide equivalent annually through on-site nitrogen gas generation. Using our modular approach, the seven module system is equipped with 88% redundancy. If a generator needs to be powered down for service, or an unexpected shutdown, production is not lost. The remaining 6 modules will continue to operate without interruption. If the plant chooses to expand production beyond the output capacity of the 7 module system, additional modules can be added to the system without interruption, ensuring the existing installation is never obsolete.

Project Details

Nitrogen Gas Generation System for Laser Cutting

by Purity Gas Inc.

by Purity Gas Inc.