Nitrogen Generation

The Economical and Eco-Friendly Alternative to Traditional Nitrogen Delivery

Find out if nitrogen generation makes sense for your business.

What is nitrogen generation?

Nitrogen gas generation is a process that separates and captures the nitrogen molecules in the air, while disposing of the oxygen and trace gases. NITROCENTER® is a nitrogen generation system that delivers nitrogen on-demand, engineered to your application requirements.

The benefits of on-site nitrogen generation

Each industry and application will require varying nitrogen concentration levels, referred to as "purity." The ability to control purity, along with pressure and volume, is what drives rapid ROI.

- Save up to 90% vs. traditional delivery

- Reduce electricity consumption

- Stop frequent diesel truck deliveries

- Achieve ROI in as little as six months

- Eliminate safety risks from handling liquid nitrogen and gas cylinders

- Control your own nitrogen supply

Nitrogen generation that works for you

On-site nitrogen gas generation can be achieved through pressure swing absorption (PSA), or membrane separation technology. Purity Gas can deploy both, and the technology used is largely dependent on the purity required for your application.

A. Pressure Swing Absorption (PSA)

How it works: PSA systems use a carbon molecular sieve (CMS) and absorption principles to separate the nitrogen molecules from a compressed air supply.

Ideal for: High-flow applications requiring 95% - 99.999% nitrogen purity.

Key Features

NITROCENTER® systems based on PSA technology are centered around two design principles: High-Pressure Storage or On-Demand Generation, to offer cost-reducing options for low-volume and high-volume nitrogen users.

Below are the typical parameters for each principle. Every client is unique and your NITROCENTER® is always customized to your needs.

Design Principle

High-Pressure Storage

On-Demand Generation

How It Works

Generates nitrogen during no or low production use

Generates nitrogen as the process requires it

Nitrogen Pressure

High: Stored at 4,500 psig and regulated to the process requirement

Low / Mid: As needed up to 450 psig and regulated to the process requirement

Nitrogen Consumption

Less than 12 hrs/day

More than 12 hrs/day

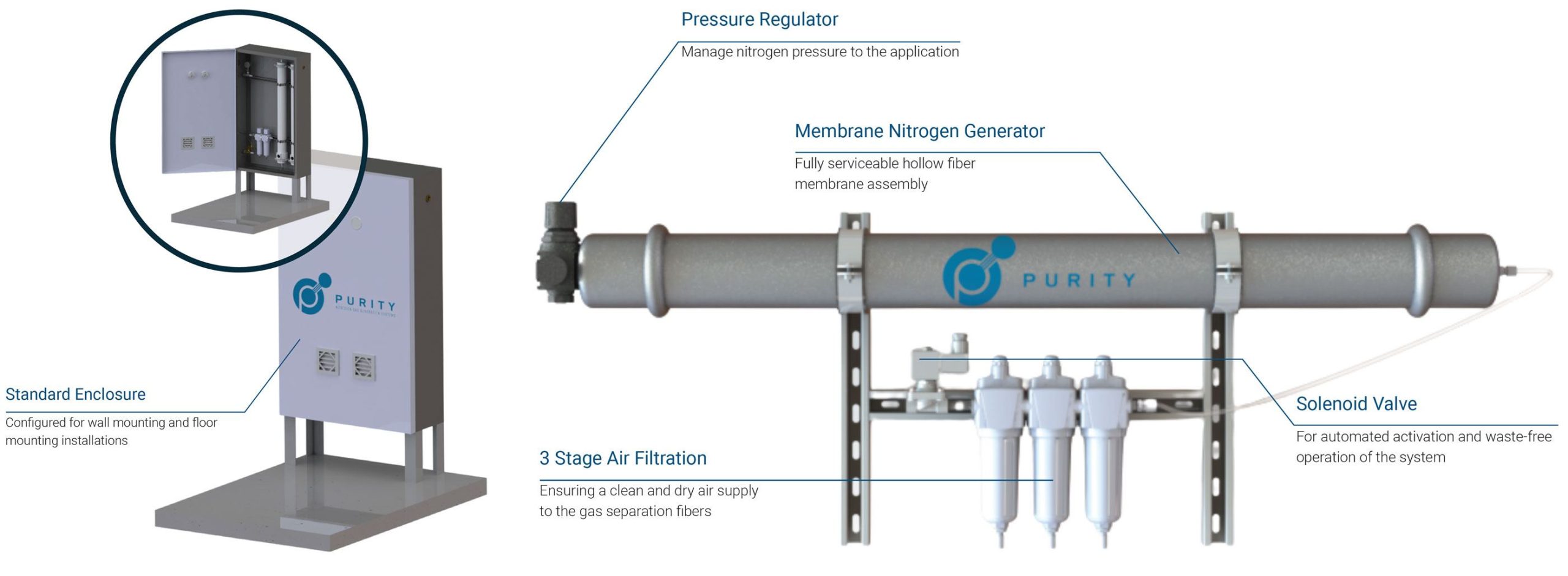

Nitrogen Generators vs. Nitrogen Generation Systems

A quick web search will display dozens of nitrogen generators for sale. These out-of-the-box products are just one component of an entire system. A nitrogen generation system not only contains all of the required components, but it’s designed as a cohesive solution that meets your technical requirements.

Purity Gas takes nitrogen gas generation to the next level. As your integration partner, we’re committed to customizing a system that maximizes ROI — bringing nitrogen generation down to the lowest possible cost.

Poor nitrogen system design can increase capital cost and cost of ownership by up to 800%.

How to select the right nitrogen generation provider

Just because your business consumes nitrogen doesn’t make on-site nitrogen generation a wise investment. A reputable nitrogen generation manufacturer will offer an initial assessment or comprehensive nitrogen audit to determine feasibility.

Key considerations when evaluating a nitrogen generation provider

Does the provider offer …

- Analysis of your current nitrogen usage?

- Technology and viability recommendations?

- The payback period and annual ROI of a system?

- Estimated carbon footprint reduction?

- A more detailed nitrogen audit?

Frequently Asked Questions

Know — with certainty — if on-site nitrogen generation is right for your business.

Not quite ready for an audit?

Start with our free assessment ›

Learn more

Nitrogen Gas Generation Resources

Your free assessment includes:

Nitrogen usage analysis

Technology selection & viability study

Payback period

Annual ROI

Installation assessment

Carbon footprint reduction